Uncategorized

How to choose the right carton box for your packaging needs

In the world of commerce, logistics, and storage, the humble carton box is one of the most critical yet often overlooked components of a successful operation. It’s the first line of defense for your products, a mobile billboard for your brand, and a key factor in your shipping costs and customer satisfaction. But with so many options available, how do you ensure you’re choosing the right one?

Selecting the perfect Corrugated Carton Box isn’t just about finding a container that fits; it’s a strategic decision that impacts everything from product safety to your bottom line. A box that is too weak can lead to costly damages and returns, while a box that is over-engineered means you’re paying for protection you don’t need.

This comprehensive guide will walk you through everything you need to know, from the basic anatomy of a Corrugated Box to the specific factors you should consider, ensuring you can make an informed decision that perfectly suits your packaging needs.

Mục lục

What is a carton box?

Before you can choose the right box, it’s essential to understand what gives it its strength. A carton box is a paper-based packaging solution made primarily from corrugated fiberboard, also known as corrugated carton box.

The magic of a Corrugated Carton Box lies in its unique, layered structure. It’s not just a single piece of thick paper; it’s an engineered material consisting of two main components:

- The Liner: This is the flat, smooth paper that makes up the inner and outer surfaces of the board. It provides a clean surface for printing and acts as a barrier.

- The Medium or Flute: This is the wavy, arched layer of paper sandwiched between the liners. This fluting is the core of the box’s performance. It creates a series of connected arches that are capable of supporting significant weight, providing exceptional cushioning against shocks and impacts.

This simple combination of liners and a fluted medium creates a material that is surprisingly strong, rigid, and lightweight. The specific arrangement and number of these layers determine the box’s type and strength.

The 3 main types of carton boxes: Which level of protection do you need?

The most common way to classify a carton box is by the number of walls or layers it has. Each level offers a different degree of strength and is suited for different applications.

a. 3-Layer Carton Box (Single Wall)

This is the most common and versatile type of Corrugated Box on the market. It consists of one layer of fluting sandwiched between an inner and outer liner.

- Structure: Liner – Flute – Liner

- Key Characteristics: Lightweight, cost-effective, and provides good, all-around protection for a wide variety of items.

- Best For:

- E-commerce shipments of lightweight goods (apparel, books, cosmetics).

- Retail packaging and product displays.

- Short-distance shipping and local deliveries.

- General storage of documents and household items.

b. 5-Layer Carton Box (Double Wall)

For heavier, more fragile, or high-value items, the 5-Layer Carton Box offers a significant upgrade in protection. It features two layers of fluting and three liners.

- Structure: Liner – Flute – Liner – Flute – Liner

- Key Characteristics: Significantly stronger and more rigid than a 3-layer box. It offers superior stacking strength and enhanced cushioning against impacts.

- Best For:

- Shipping heavier products (e.g., small appliances, electronics, machine parts).

- Protecting fragile items (e.g., ceramics, glass, sensitive instruments).

- International and long-haul shipping where boxes will be handled multiple times.

- Stacking on pallets in a warehouse for extended periods.

c. 7-Layer Carton Box (Triple Wall)

This is the heavyweight champion of the corrugated world. The 7-Layer Carton Box is an industrial-strength solution designed for the most demanding packaging challenges. It has three layers of fluting and four liners.

- Structure: Liner – Flute – Liner – Flute – Liner – Flute – Liner

- Key Characteristics: Offers the ultimate in strength, durability, and puncture resistance. It is often used as a direct, lighter-weight alternative to wooden crates.

- Best For:

- Shipping extremely heavy industrial equipment and machinery.

- Transporting large automotive parts.

- Bulk shipments of dense materials.

- Any application where maximum protection is non-negotiable.

Decoding the Flutes: A, B, C, & E Profiles

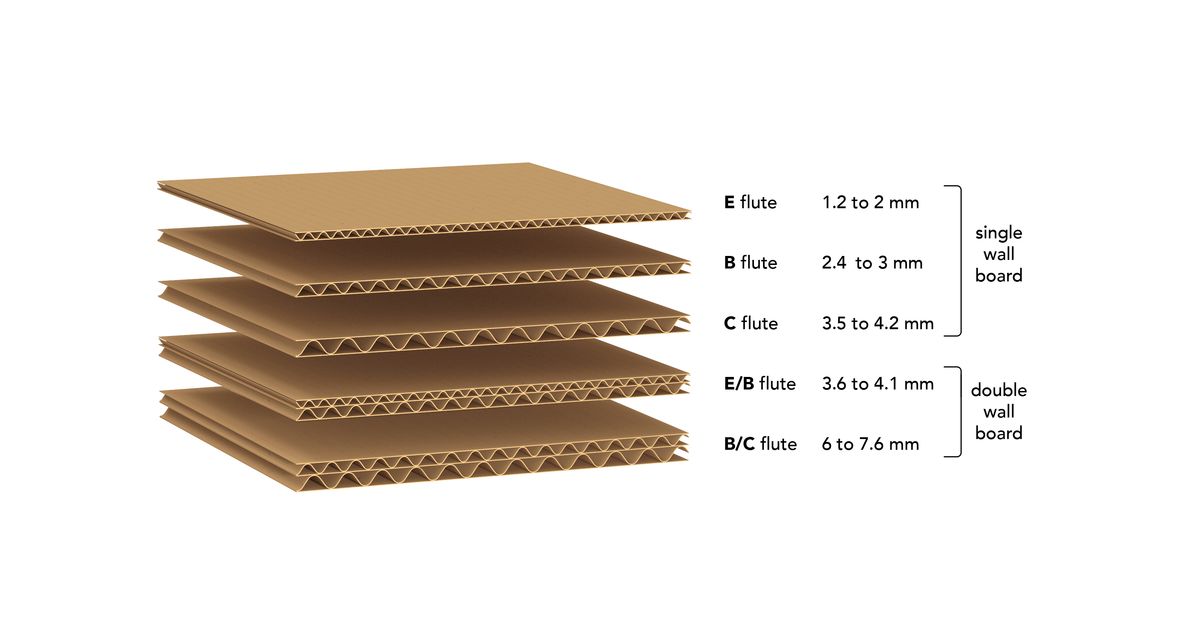

The flute profile refers to the size and shape of the wavy medium. Different flute profiles offer different benefits, and choosing the right one is key to optimizing your box.

- A-Flute: The thickest flute, providing the best cushioning and stacking strength. Ideal for protecting extremely fragile items.

- C-Flute: The most common flute profile used in standard shipping boxes. It offers an excellent all-around balance of strength, cushioning, and durability.

- B-Flute: Thinner than C-flute, providing good crush resistance and a smoother, flatter surface that is excellent for printing high-quality graphics.

- E-Flute: A very thin and fine flute, primarily used for retail packaging (like pizza boxes or cosmetic boxes) where print quality and a premium feel are important.

For double-wall (5-Layer Carton Box) and triple-wall (7-Layer Carton Box) constructions, these flutes are often combined (e.g., “BC Flute”) to leverage the benefits of each profile in a single board.

A practical checklist: How to choose your perfect carton box

Now that you understand the components, ask yourself these key questions to determine the perfect carton box for your needs:

Question 1: What is the weight and fragility of your product?

- Lightweight & Durable (< 10kg): A 3-Layer Carton Box is likely sufficient and most cost-effective.

- Medium Weight & Moderately Fragile (10-30kg): A 5-Layer Carton Box is the recommended choice for better protection.

- Heavy, Fragile, or High-Value (>30kg): A 5-Layer or even a 7-Layer Carton Box is essential to ensure safety.

Question 2: What are your shipping and storage conditions?

- Stacking: Will the boxes be stacked high in a warehouse or container? If so, you need a box with high compression strength, like a C-flute or any double-wall configuration.

- Transit: Is it a short local delivery or a long international journey with multiple handling points? Long-haul and export shipments demand the durability of a 5-layer or 7-layer box.

- Environment: Will the box be exposed to high humidity? A stronger, thicker board will resist moisture better.

Question 3: What are your branding and printing needs?

- Basic Information: If you only need to print a simple logo and handling instructions, a C-flute or B-flute surface is adequate.

- High-Quality Graphics: If your Corrugated Box is part of your retail presentation and requires detailed, high-resolution printing, an E-flute or B-flute surface is the best choice.

Why Choose Micopak for Your Carton Box Needs?

At Micopak, we combine technical excellence with sustainable innovation. Our commitment includes:

-

Custom packaging solutions

-

Modern automated machinery

-

High output: up to 1 million boxes/month

-

Custom printing & die-cutting capabilities

-

Eco-conscious production using recycled or FSC-certified paper

Whether you’re shipping local or exporting globally, Micopak delivers carton boxes that meet your performance, branding, and sustainability goals.

Your packaging is an investment

Choosing the right carton box is a critical business decision. It is an investment in your product’s safety, your brand’s reputation, and your customers’ satisfaction. By taking the time to understand the different types, flute profiles, and your own specific requirements, you can select a packaging solution that delivers performance and value.

Don’t leave your product’s safety to chance. A well-chosen Corrugated Carton Box is the foundation of a successful shipping strategy.

If you are still unsure which option is best for you, our packaging experts are here to help. Contact us today for a free consultation and a custom quote based on your unique needs!

Whatsapp / Mobile: +84.975.960.929

Email: sales@micopak.vn

Alibaba: https://micopak.trustpass.alibaba.com/