Paper slip sheets are thin sheets made of Kraftliner paper that come in a variety of shapes and sizes to fit a range of needs. Similar to a pallet, they are placed underneath a load and are used to push or pull the load on and off of the forklift’s forks or platens.

Features

- Durable and puncture-resistant

- High tensile strength

- Made from multiple plies of 100% virgin kraft linerboard

- Custom-designed to varying sizes, styles and thicknesses

- Smart Environmental Choice

- 100% Recyclable

Advantages of Paper Slip Sheets

- Using paper slip sheets instead of wooden pallets allows for 12–15% more products in material handling containers.

- Slip sheets do not require maintenance and can easily be replaced.

- Significant reduction in material handling costs. Slip Sheets weight 1/20 as much as pallets, which means major savings on shipping cost. Material costs can be decreased 80% or even more when compared to wooden pallets.

- Decreases loading/unloading time by up to 60%

- Better use of space in containers and vehicles.

- Slip Sheets have a thickness of 0.6 – 0.8 mm, a wooden pallet has approx.15 cm. Slip Sheets have a weight of 620 gr/m2 whereas wooden pallets have a weight of 15 kg. You save 30 cm per m2 in a container and per load around 460 kg per container if you double stock pallet units in the container.

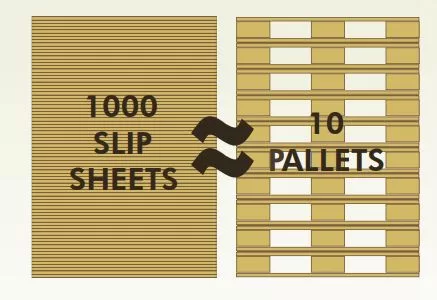

- Minimum space is required for storage of the sheets, thus reducing warehousing costs:

1,000 Slip Sheets = 1 m3

1,000 pallet = 70 m 3

- Can be customized to fit any size load.

- Eliminates the need for pallet exchange.

- Reusable and reliable.

- 100% recyclable.

- Is cost-effective.

- Unlike wooden pallets, paper slip sheets are not subject to phytosanitary restrictions

For more information, please contact us:

MICOPAK JSC

Factory 1: Lot D, Dong Van II Industrial Park, Dong Van Ward, Ninh Binh

Factory 2: Kieu Thi Hamlet, Chuong Duong Commune, Hanoi city

Factory 3: No 883/15, My Phuoc – Tan Van Street, Chau Thoi Quarter, Dong Hoa Ward, Ho Chi Minh city

Hotline / Whatsapp: +84 967.131.614 / +84.975.960.929

Email: sales@micopak.vn

Website: www.micopak.vn

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.